PCB® includes a calibration certificate with every charge accelerometer. This certificate documents the characteristics of each accelerometer and provides exact values for several key specifications. A sample calibration certificate is shown in Figure 6.

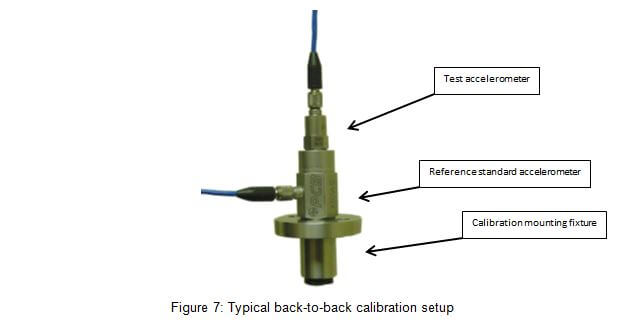

Back-to back calibration is performed with the test accelerometer mounted onto a reference accelerometer. This technique provides a quick and easy method for determining the sensitivity of an accelerometer over a wide frequency range.

The reference accelerometer is an extremely accurate device with specifications traceable to a recognized standards laboratory. It is possible to vibrate both accelerometers and compare output data by securely mounting the test accelerometer to the reference standard accelerometer.

The ratio of the output voltages is also the ratio of the accelerometers’ sensitivities because the acceleration applied to them is the same. The sensitivity of the reference accelerometer is known so the sensitivity of the test accelerometer can be calculated.

Recalibration services are offered for PCB® manufactured accelerometers as well as those produced by other manufacturers. Our internal metrology lab is certified to ISO 9001 and accredited by A2LA. The equipment used during calibration is directly traceable to NIST (National Institute of Standards and Technology).