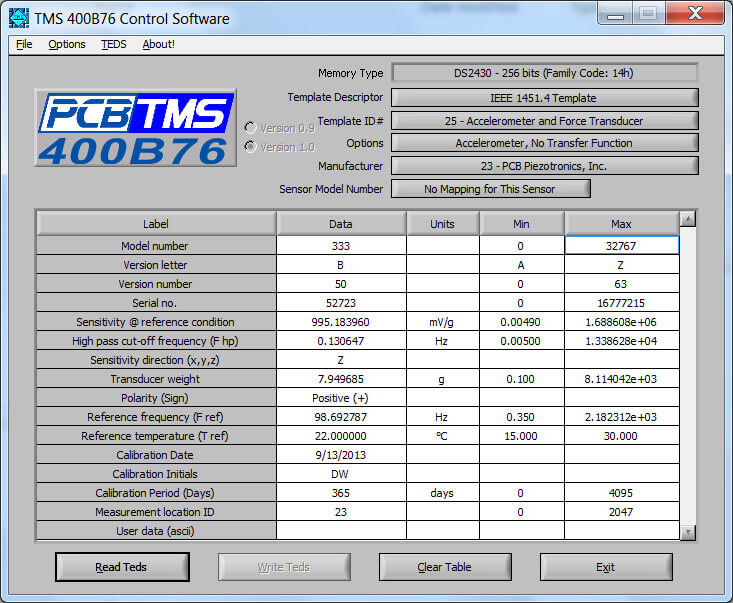

TEDS is non-volatile memory within a sensor that is utilized for storing information about that sensor. The manufacturer can program initial information into the TEDS chip. This can include manufacturer name, sensor type, model number, serial number, and calibration data. Memory space allocation permits the end user to add information such as location identification, latest calibration date, and other unique sensor related attributes.

The sensor operates in a mixed mode fashion (analog or digital). The information stored in the TEDS chip is downloaded when the sensor operates in digital mode. In analog mode, the sensor functions normally as a measurement device. A suitable TEDS signal conditioner or data acquisition front end is used to access the sensor memory. The digital communication occurs over the same wires ordinarily used for analog measurement signal transmission. Once the pertinent data has been transferred from the sensor, the memory circuit is switched off and the sensor resumes normal analog operation. A TEDS sensor may be used with a conventional signal conditioner however, there would be no access to the memory. A conventional sensor may also be used with a TEDS signal conditioner but there would be no TEDS functionality.

For universal applicability, the architecture of this technology is defined by the IEEE 1451.4 Smart Transducer Interface standard. By conforming to a universal standard, any TEDS sensor will be capable of being addressed by any TEDS signal conditioner, regardless of manufacturer. PCB® Group Inc. has products that comply with the standard and has provided thousands of TEDS enabled sensors and signal conditioners for installations throughout the world.