IMI Sensors technical support is unmatched. Years of application engineering experience have yielded technical tips to help maintenance teams to protect their critical machinery against unscheduled downtime. Check them out!

USB Programmable Smart Vibration Switch

Capture the Abilities of an Electronic Vibration Switch at a Mechanical Vibration Switch Price

Mechanical switches are prevalent in industrial vibration applications because of their price point, not because of their accuracy or precision. On the contrary, electronic vibration switches are very precise but less frequently used because of their higher upfront price.

IMI Sensors offers the Smart Vibration Switch (Model 686), a patented product (U.S. Patent No. 7,767,919) that provides the abilities of the electronic vibration switch at the mechanical vibration switch price. In addition, the Smart Vibration Switch offers several other features that are unique among products in the vibration switch market.

To fully appreciate the advantages of the Smart Vibration Switch, let’s first examine the weaknesses of the mechanical switch when it comes to precision and accuracy.

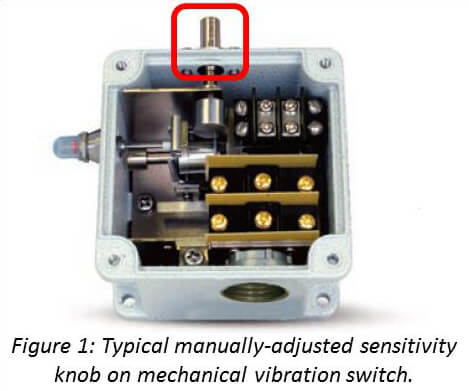

Mechanical switches rely on a spring-latch mechanism to trip when vibration exceeds the pre-set threshold/setpoint. The setpoint is regulated by a sensitivity adjustment knob, typically accessible to a user on the exterior of the switch housing. See Figure 1 for an illustration of a typical switch and its sensitivity adjustment knob. The setting of the threshold is an imprecise process at best, during which the trip point of the switch is determined through repeated equipment start-ups and the threshold is then set to just slightly less sensitive than that trip point.

Without time delay capabilities, the mechanical switch is nothing but a shock switch as transient events (sometimes completely unrelated to machine vibration and condition) can easily cause false trips and shutdowns. After several shutdowns, users often adjust the mechanical switch threshold to the least sensitive possible to prevent these false trips. Unfortunately, the user has inadvertently eliminated the effectiveness of the switch by removing most or all of the protection provided by the switch.

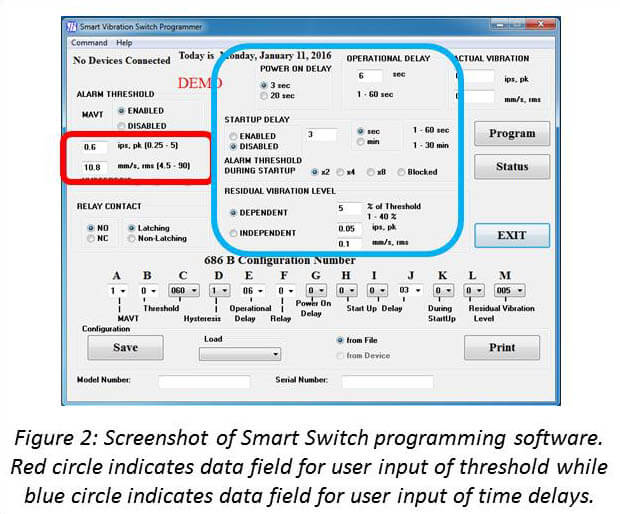

The IMI Smart Vibration Switch, like electronic switches, avoids the problems associated with mechanical switches by utilizing an accelerometer for vibration sensing rather a spring-latch mechanism. In a Smart Vibration Switch, the setpoint is adjusted electronically through the use of programming software. (The software can be installed on most PCs. The sensor interfaces with the computer through a cable that includes a USB connector on the computer end and a two-socket connector or terminal block adapter on the sensor end.) The ability of a user to set a specific numerical value (in velocity) for the threshold puts an end to the era of unreliable setpoints. See Figure 2.

The IMI Smart Vibration Switch, like electronic switches, avoids the problems associated with mechanical switches by utilizing an accelerometer for vibration sensing rather a spring-latch mechanism. In a Smart Vibration Switch, the setpoint is adjusted electronically through the use of programming software. (The software can be installed on most PCs. The sensor interfaces with the computer through a cable that includes a USB connector on the computer end and a two-socket connector or terminal block adapter on the sensor end.) The ability of a user to set a specific numerical value (in velocity) for the threshold puts an end to the era of unreliable setpoints. See Figure 2.

In addition to allowing the input of threshold data, the programming software gives the user access to programming for three different time delays:

- Power On Delay: Delay occurring when non-powered switch has power applied to it.

- Start-Up Delay: Delay occurring when non-operating equipment on which the switch is mounted begins operation.

- Operational Delay: Delay occurring when actual vibration exceeds the vibration threshold. The actual vibration must exceed the vibration threshold for the entire delay time period in order for the switch to trip.

In addition to providing the abilities of an electronic switch at the price of a mechanical switch, the Smart Vibration Switch offers several other unique features as described below.

- Small housing with multiple connector options: Unlike typical vibration switches that are housed in square, junction box-sized housings, the Smart Vibration Switch is housed in a compact, accelerometer-style housing. This allows for easy mounting of the Smart Vibration Switch with the installation of a single stud. The Smart Vibration Switch is available with a 2-pin MIL connector, integral polyurethane cable, integral armored cable or terminal block to accommodate a wide variety of applications, including potentially-explosive environments. See Figure 3.

- Quick-set process for threshold adjustment: In addition to offering the threshold setting capabilities of the programming software, the Smart Vibration Switch also offers a quick-set option through the Magnetically-Activated Vibration Threshold feature. MAVT™ quick-set programming allows for the simplest of threshold settings. Simply touch the magnet to the side of the switch when it is on the machine to automatically set the threshold at two times the current vibration level. See Figure 4.

- Programming security: Because all Smart Vibration Switch programming is executed through the programming software, the possibility of purposeful or inadvertent changing of programming setpoints is eliminated.